The Laboratory provide a comprehensive service of technological – technical works (crushing, milling, gravitational separation, flotation, magnetic separation), granular and mineralogical analyses (X-ray, DTA) for the needs of geological research, exploration and the technology development of raw materials treatment, as well as the wastes utilization, the soil and the sediment decontaminations.

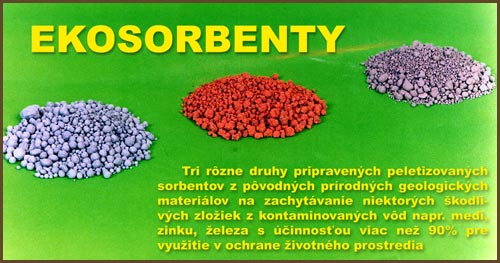

In addition, the Laboratory offer wide range of research to application of the different kinds of sorbents for the remediation of surface water and groundwater from organic pollutants, inorganic components and toxic elements.

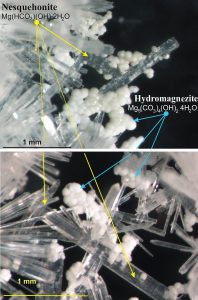

In the field of liquidation of CO2 by carbonatization are used high-pressure reactors to tests of harmful waste material –asbestos-bearing ultramafic rocks, fly ash, slag or older ecologically unsuitable building materials.

The Department ATNS Košice was awarded the Award of the Minister of the Environment for extraordinary results and long-lasting contribution to environmental care and environmental development at 2016.